Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

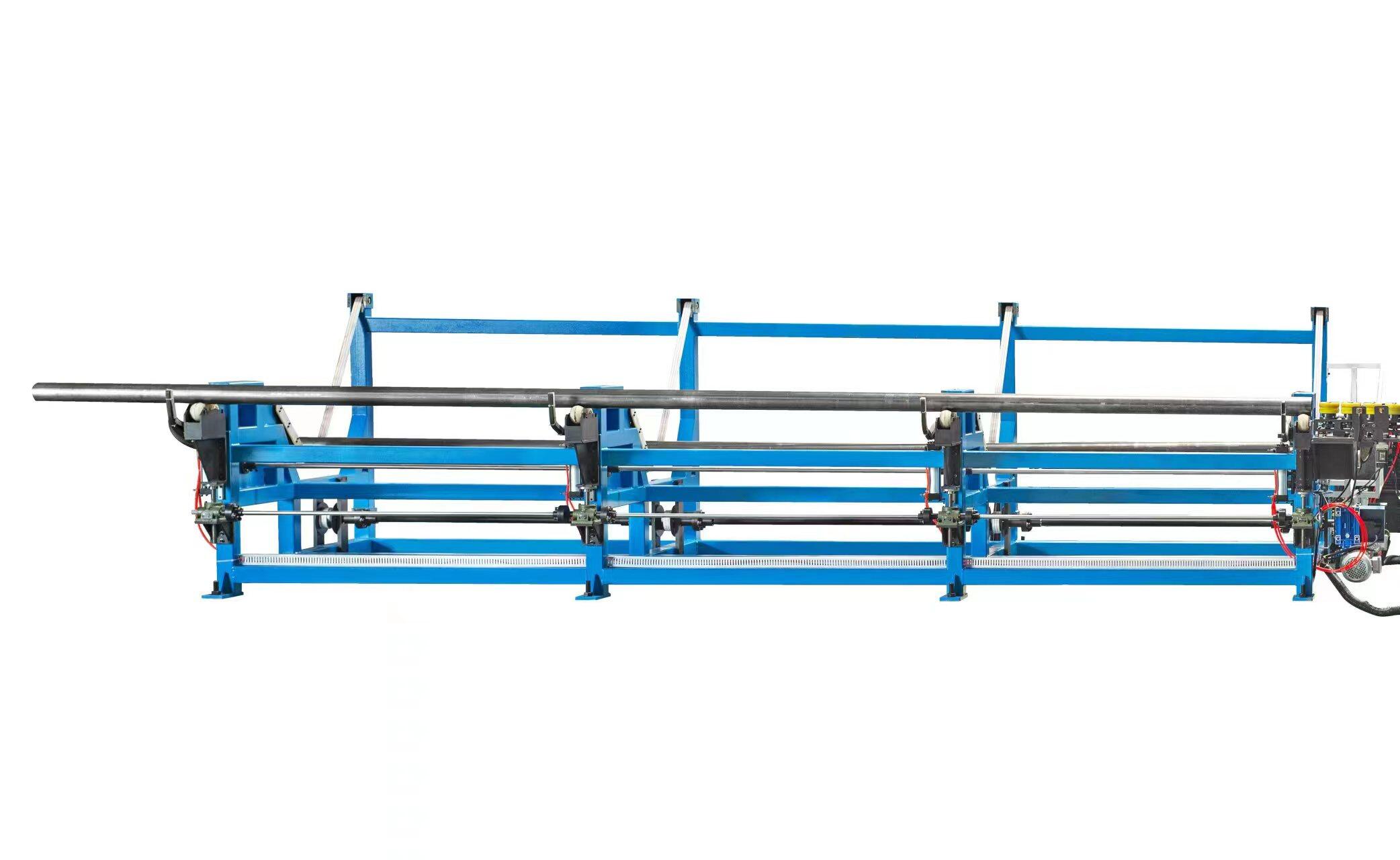

Semi-automatic loading rack

The one-button semi-automatic loading rack is simple to use and can increase work productivity. However, when changing the kind of tube, you must manually adjust the size restriction of the tube loading. The equipment is light and has a small footprint, so it can be transported and docked with ease. The structure is straightforward, which can account for the stability of the equipment.

Semi-automatic loading rack

The semi-automatic loading rack is easy to operate, with one-button loading (you need to manually adjust the size limit of the tube loading when changing the tube type), which can improve work efficiency. The structure is simple, which can take into account the stability of the equipment, and is cost-effective; the equipment is light and has a small footprint, which can be easily moved and docked.

The Structure of the Semi-automatic loading rack

- Warehouse

The truss is the basis for supporting the movement of the upper and lower manipulators and is assembled from columns and beams. The columns and beams of the truss are made of large-section high-strength thick-walled steel, and the overall rigidity of the truss is good.

- Feeding system

The function of the feeding system is to realize the steel pipe grabbing and feeding to the laser pipe-cutting machine. The composition of the structure: sprocket, cylinder, guide rail, drive chain, etc.

The Workflow Analysis of the Semi-automatic loading rack

- Pipe into the stack: Manually put a bundle of pipes on the stack;

- Power-on reset: Turn on the power supply, and all components start to reset;

- Manual feeding: Manually push the material stack into the pipe, and the chain drives the pipe to the feeding bracket;

- Dividing: When the pipe moves to a certain position of the feeding bracket, the distributing mechanism sorts the plates to ensure that a single pipe enters the feeding mechanism;

- Feeding: When the pipe reaches the designated position, the feeding mechanism acts to send the pipe to the target position of the laser pipe-cutting machine;

- The laser pipe-cutting machine clamps the pipe and completes the cutting.

To ensure the safety of the operation of the entire automation system, in the process of operation, necessary manual intervention and auxiliary control are required.